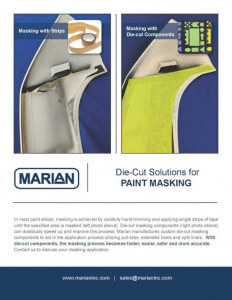

In most paint shops, paint masking is achieved by applying single strips of tape until the specified area is masked. Die-cut masking components drastically improve this process.

Marian manufactures custom masking components to fit the precise shape of the masked area. Die-cut masking parts also simplify and speed up the application process utilizing pull tabs, extended liners, and split liners. Marian maintains long-standing preferred converter relationships with leading masking tape manufacturers like 3M and tesa®.

Marian can quickly provide material samples and prototypes. Contact us today to discuss your paint masking needs or to learn more!

Benefits of Die-cut Paint Masking vs. Strips

Blog Posts

Solution Case Study

Download this solution case study to read about a company who implemented a die-cut masking components into their process. Results achieved: 3x faster application, a safer process that was easier to train, maximized productivity and required 75% less rework. Read more…